Founded in 2004, an&angel use state-of-the-art methods to create aerial and elegant bowls of the highest quality. Company's creative director, designer and glass artist Artis Nimanis, is fascinated by possibilities and continues to challenge conventions by experimenting with the latest technologies. One of his trademarks are experiments to combine glass with metal. He tried several options till he came to the stainless steel coating.

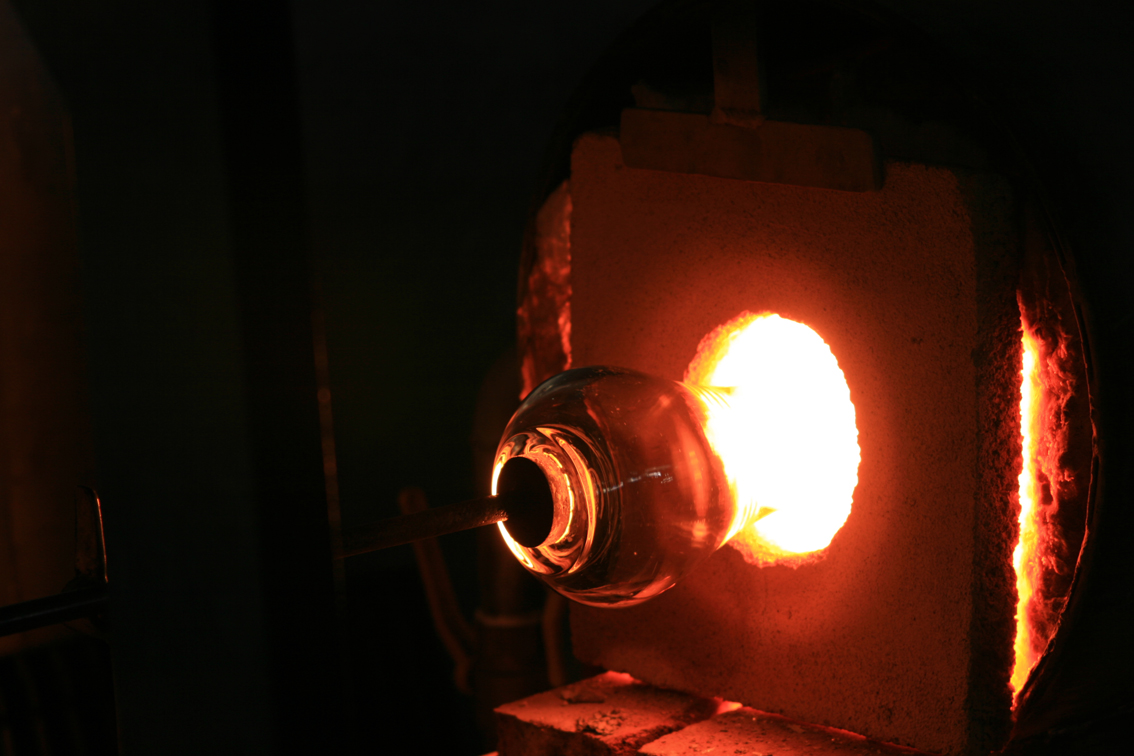

The process of coating the bowl with a metal happens by placing each bowl in a vacuum chamber, where they are coated with stainless steel and metal changes from hard to liquid. Stainless steel tiny drops, which actually more remind fog, go down due to the gravity and after they have covered all the surface, are "burned" with a plasma. This technique is used in air and space researched technology.

The main problem, faced by our designer Artis Nīmanis trying to connect metal with glass, was the different electrical conductivity of each material, what prevented to find qualitative and enjoyable result.

This high-tech method is also applied for coating different metal parts used for space research machines, because the vacuum coating applied to the metal, significantly improves properties of the coated material.

Method is based on treatment of the material in a high vacuum environment where metal is transformed into to a fog, which due to gravity lands on a surface to be coated, and on the final stage is burn by plasma assistance.

As a result glass creations are developed that are minimalistic in their aesthetics, functional in their design and unique by virtue of their hand-crafted nature.

an&angel - perfecting your living space since 2004